The conventional image of mineral processing often involves dusty mines, strenuous labour, and environmental degradation. However, an extraordinary transformation is currently underway, driven by a fascinating blend of emerging technologies. Say goodbye to pickaxes and smelters, as the future of mineral extraction resembles an advanced factory, where robots, guided by artificial intelligence (AI), and inspired by nature’s alchemy, uncover hidden treasures. Welcome to the era of the mineral maker, where technology is revolutionizing the industry from the ground up.

1. AI & Machine Learning: Precision Extraction, Elevated Efficiency

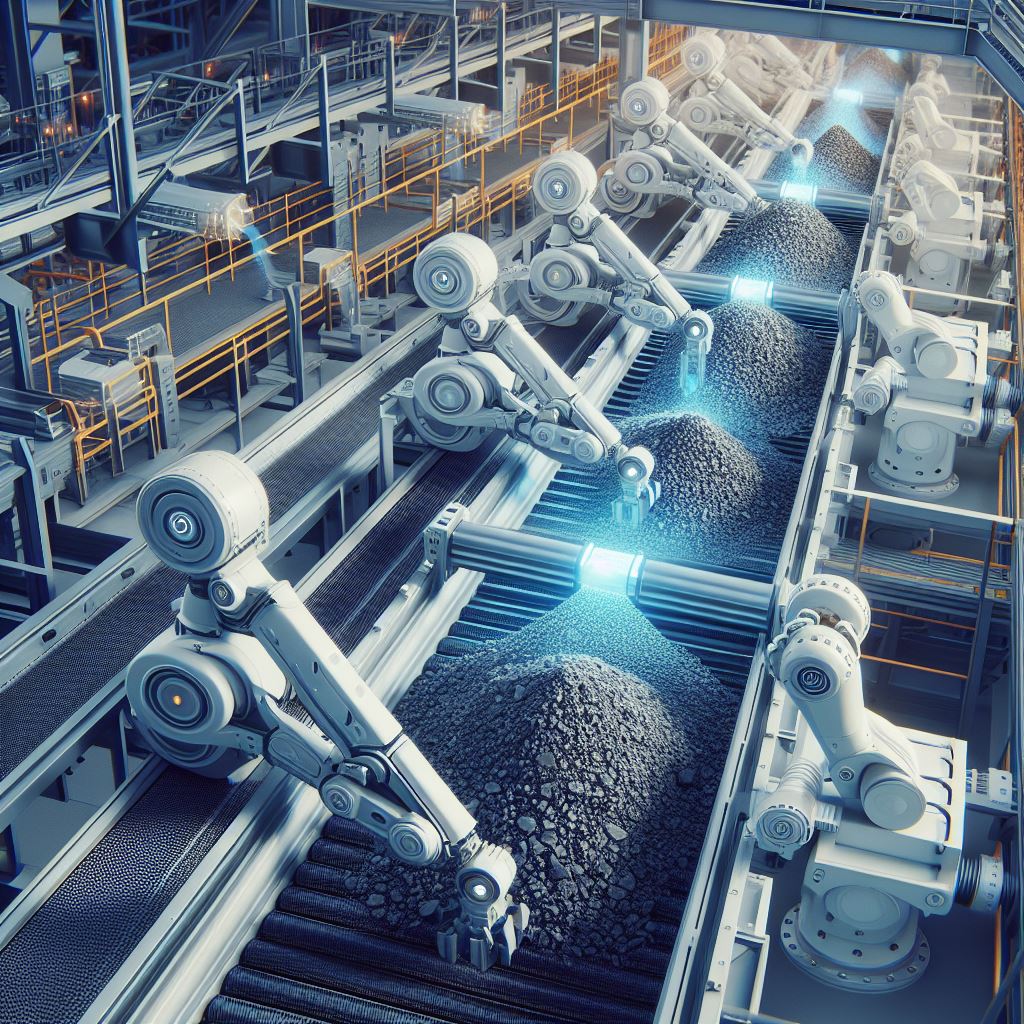

Imagine a conveyor belt transporting ore, not operated by fatigued workers, but rather by cameras and sensors, constantly feeding data to a voracious AI system. This intelligent algorithm, honed on millions of mineral images, precisely identifies valuable resources. The days of labour-intensive sorting are gone; AI-guided robotic arms meticulously extract desired minerals, leaving worthless rock behind. This is not science fiction; it’s the reality of sensor-based sorting, powered by AI and machine learning. The advantages are substantial: increased resource recovery, reduced waste generation, and the ability to extract minerals that were once considered uneconomical, expanding the industry’s frontiers.

2. Biohydrometallurgy: Nature’s Alchemist, Unleashed

Leave behind towering smokestacks and energy-hungry smelters. Biohydrometallurgy taps into the microscopic miners of nature – microbes. These minuscule alchemists dissolve and extract metals from ores using their metabolic prowess. Imagine bacteria feasting on rock, extracting valuable minerals such as gold and copper. This bio-inspired process is not only eco-friendly and efficient but also opens doors to processing complex ores that traditional methods struggle with. Picture extracting critical minerals from electronic waste or unlocking rare earth elements from discarded batteries – biohydrometallurgy is making it possible, paving the way for a more sustainable future.

3. Automation & Robotics: From Human Muscle to Machine Precision

Step into a contemporary mine, and you’ll be greeted by a symphony of robots instead of a cacophony of pickaxes. Autonomous vehicles navigate underground tunnels with laser-guided precision, transporting ore loads while humans oversee operations from safe stations. These tireless robotic workhorses not only enhance safety and reduce physical strain but also boost productivity and optimize operations. Imagine automated drilling rigs tirelessly boring through rock or robotic arms expertly loading ore wagons without error. Automation and robotics are reshaping the mining landscape, making it more efficient, safer, and leaner.

4. Blockchain: Illuminating a Previously Opaque Path

The shadowy world of mineral sourcing is being illuminated by the transformative power of blockchain. This decentralized ledger tracks every step of a mineral’s journey, from extraction to processing and beyond. Envision scanning your phone to reveal the ethical and sustainable story behind the material in your smartphone. Blockchain fosters transparency, ensures ethical sourcing, minimizes conflict minerals, and empowers consumers to make informed choices. This newfound transparency promises to revolutionize the industry, promoting sustainable practices and responsible sourcing.

5. Circular Economy: Transforming Waste into Wealth

The traditional concept of “waste” is undergoing a radical transformation. Emerging technologies like hydrometallurgical recycling and urban mining are recovering valuable resources from what was once discarded. Consider the recovery of precious metals from electronic scrap or the extraction of rare earth elements from discarded batteries. These advancements are closing the loop on the mineral lifecycle, turning waste into a valuable resource and diminishing the industry’s environmental footprint. The vision of a circular economy is no longer just an aspiration; it is becoming a tangible reality, driven by innovative technologies and a shift in mindset.

The Future is Now: A Kaleidoscope of Possibilities

What we’ve glimpsed here is merely a preview of the breath-taking future of mineral processing. It’s a future where technology not only enhances efficiency but also lays the foundation for a more sustainable and responsible industry. The road ahead may still be dusty and fraught with challenges, but one thing is unmistakable: the future of mineral processing belongs to the makers, not the miners. It’s an era where cutting-edge tech harmonizes with nature’s wisdom, transforming a historically polluting industry into a positive force for the world.

Join the Conversation:

This transformation isn’t just a technological shift; it’s a call to action. Stay tuned for our forthcoming blog series, where we’ll delve deeper into each of these exciting technologies and their profound impact on the industry. Share your thoughts and questions in the comments below – let’s embark on this exploration of the future of mineral processing together!